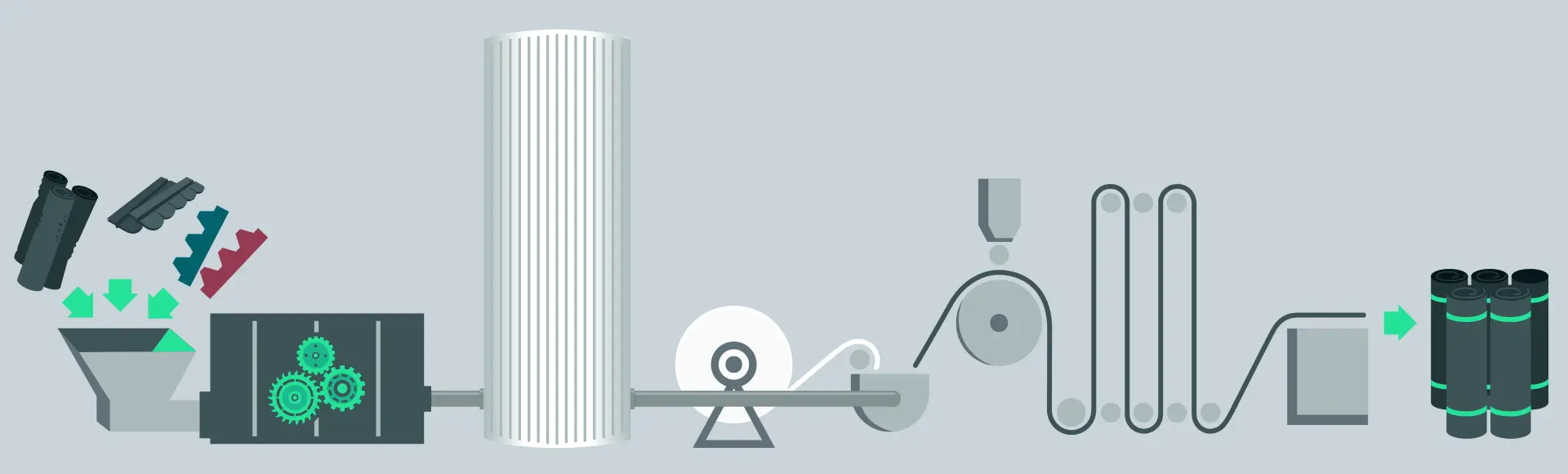

Asphalt rolled roofing materials and shingles scrap are reprocessed without primary cutting to pieces. The rolled roofing materials can be fed in the equipment in the rolled state.

Option 1

Extra Fine Shredding

Extra Fine Shredding Equipment can be installed directly at the asphalt roofing materials manufacturing facility.

If it is not possible to place REMA reprocessing equipment directly at customer’s manufacturing facility (lack of industrial space, etc.), it can be installed at the manufacturing plant developed and built by REMA, aiming at the production of new asphalt roofing materials.

Mineral particle size after reprocessing (extra fine shredding) with REMA equipment:

Polyester*, glass and cellulose backings are shredded to individual fibers with size less than 1.0 mm.

*Power consumption and costs of maintenance wear-and-tear increase by 15-20% when reprocessing materials with polyester backings.

power consumption

max. 60 kW per ton

costs of maintenance wear-and-tear

max. 30 USD per ton

Option 2

Fine Shredding and Pelletization

Mineral particle size after reprocessing (fine shredding) with REMA equipment:

Polyester*, glass and cellulose backings are shredded to individual fibers with size less than 5.0 mm.

*Power consumption and costs of maintenance wear-and-tear increase by 15-20% when reprocessing materials with polyester backings.

power consumption

max. 35 kW per ton

costs of maintenance wear-and-tear

max. 20 USD per ton